It all started with the gas cap bodge. The rest of our race across the country to get to Flagstaff in time for Overland Expo became one long series of increasingly urgent mechanical issues.

We were stopped at a gas station to fill up, take a break and walk the dogs. When we got back in the van and started to drive up the on-ramp onto the interstate, we noticed a “thwap, thwap, thwap” sound bouncing off the jersey barrier on the side of the ramp. It was coming from our van. Kay described it like the sound of a playing card in bicycle spokes, only “meatier”.

We drove on. The next morning, when we started her up and attempted to drive off, it had gotten worse. We decided that the next time we stopped for gas, we’d take a look and see if we could figure it out. I maintained that it sounded like an exhaust sound, but not… Kay agreed, but we couldn’t figure out why it would be thwapping. Exhaust shouldn’t be too bad, though, if that’s what it was, because there are all these exhaust places along the way where you can show up and they fix your problem.

When we stopped, we took the engine cover off and looked around. Nothing stood out to us, but we didn’t really know what we were looking for. Kay couldn’t spot any obvious holes in the muffler, although part of the timing belt cover was melted! I fired it up, and Kay watched from the engine compartment… and damn that’s a lot of smoke! And it’s coming from somewhere other than the end of the muffler. We spent a few minutes investigating, and Kay figured out where the smoke was coming from, and took some pictures which we then posted to TheSamba. We figured out that the thwapping sound was only happening under load - not when we were coasting, and not when we were in neutral. So we posted the details and waited for replies.

Pretty quickly, TheSamba folks had identified that we’d blown an exhaust gasket. And that we were missing some bolts in the exhaust. “Is it safe to drive like this?” we asked. The answer appeared to be “Get thee to a Napa and find a new exhaust gasket, and rob some fasteners from somewhere else to keep things intact for now.”

Performance was definitely suffering. We were barely able to limp up hills at 40-50MPH at this point. We decided to leave the interstate and head the rest of the way toward Flagstaff on state highways. We were only a few hundred miles away at this point.

We stopped at the first Napa we saw, which was more like a guy’s extended shop than an auto parts store. We showed him pictures of the gaskets we needed, and explained the problem, and he was able to look up and find the part… in Denver. If we ordered it by 3pm, they could have it in this middle-of-nowhere town in New Mexico by Saturday.

As it was Thursday, and Overland Expo started bright and early on Friday morning, we decided to try to go on. After all, it was just an exhaust gasket - the performance was definitely suffering, but it probably wasn’t fatal. Right?

Off we went on the state highways through New Mexico. Hours later, up and down more hills than I care to contemplate (sometimes falling to under 30MPH) I suggested to Kay that we hit the interstate again. The interstate is generally flatter and more direct - even if we had to go slow with our blinkers on, it seemed better than fighting up and down the steep hills. Kay agreed, so we stopped in Gallup, NM for some lunch and groceries, and then tackled the final stretch toward Flagstaff.

She huffed. And she puffed. The temperature gauge started randomly working again, and I watched it climb as we gained elevation. And then, somewhere after we’d crossed the Arizona border but still far from Flagstaff, she shut down. Period. The electrics went out, and we had nothing. No indicator lights on the dash, no response when we turned the key - nothing. Kay was driving, and coasted to the side of the road.

We hopped out, opened up the engine compartment, and were greeted with the sight of an engine completely coated in carbon from the exhaust. Everything was black and disgusting. We could barely make out individual components under all the carbon dust. Nothing looked amiss to us… but we decided that something seriously catastrophic must have happened, and this was our sign to give up.

What should we do? Flagstaff was still 135 miles away. Gallup, NM was the closest town at 50 miles back… but a quick search didn’t turn up any VW mechanics in Gallup. These things are so old that most shops won’t touch them anyway, and our particular Vanagon is a diesel and a mismatch of parts that makes her even more difficult to service. So the only logical thing seemed to be to try to get her to Flagstaff where there was at least one shop that would work on her, and possibly our acquaintance from TheSamba who knows these diesel Vanagons inside and out would be able to work on her.

Kay called AAA to arrange for a tow. We tried to get a price quote, as payday was the next day and we were perilously low on funds. We knew from our tow last year to Oklahoma City that AAA would only cover a small portion of the tow. Much confusing phone conversation later, Kay got a quote of roughly $5 per mile, and AAA would only cover the first 5 miles. We bit the bullet, because we didn’t see that getting anywhere else would be helpful… so we arranged the tow. When the driver showed up, he told us it would be $640, and no we couldn’t put it on a card, but he’d take us to an ATM where we could get cash.

Sigh.

Van loaded up, we had thankfully reached our diesel Vanagon guy and he agreed to let us tow it to his house and he’d have a look on Friday. We’d been planning to bring it to him the following week to do some work to optimize the engine anyway, but we were a week ahead of schedule and very grateful that he’d look at it. He wouldn’t speculate about our problem from what we’d described on the phone… “It could be something minor, or it could be something serious.”

When we got to his house, it was late and past dark, so he had us park in his driveway and agreed to let us sleep in the van there overnight. He had dogs inside, so we were on our own for bathroom needs, but we had a port-a-potty so we weren’t going to argue. We were just grateful not to have to pay for a hotel on top of the tow.

The next morning, Andrew opened up the engine compartment and started to look things over. The first step - one he wouldn’t recommend in most circumstances - was to hose the entire engine compartment down to try to get the carbon dust off so we could actually see what was going on. Andrew speculated that carbon was a good conductor, and the thick coating of carbon we’d accreted was enough to form a short and kill our electrics.

Once we got the engine cleaned up a bit and got into the details, Andrew found pretty quickly that the shunt I installed in the ground line on our starter battery had simply blown. It was a 100amp shunt, and it had blown under load. That had been one serious short. Once he bypassed the shunt and connected the battery again, we were able to get electrics - but there was a spark when he connected the negative line. It seemed like somewhere, some positive wire was making contact with the chassis. He didn’t like the rats nest of wiring in the engine compartment (something I hadn’t tackled yet in my electrical overhaul of the van) but it was enough to have power, so he went on to work on the exhaust gasket.

A few minutes poking around under the van, and Andrew discovered that not only had we blown the exhaust gasket and lost a few studs - we were missing 6 of 8 studs that holds the exhaust manifold and the turbo. We were down to 2. He speculated that once we lost the one bolt holding on our muffler, the exhaust functioned like a lever and every vibration was amplified, which meant the bolts on the exhaust manifold started to come undone like a zipper. Even if the electrics hadn’t blown, leaving us stranded, it might have been a good thing we didn’t keep driving with only those two studs holding things together.

As he was going to have to remove the exhaust and engine mount anyway, he decided to tackle our poor engine mount setup while he was at it. And he offered to weld in a flex section to our exhaust - something he does as standard practice when he works on these engines - so that if we do lose studs, the exhaust can still flex a bit and the vibration won’t just unzip all of our remaining studs.

We were going to have to address the air filter, as the carbon had coated everything which meant the engine had been trying to suck in filthy air through a dramatically compromised filter… but we discovered that the air filter was poorly installed - the engine was pulling air from the bottom of the filter box instead of the top, which meant it could apparently be pulling water in along with air. And whomever had installed it had left an open hole in the bottom, which meant the engine was pulling in unfiltered air, too. It was a mess, but Andrew thought he could address it, too, and install it properly. Huzzah! We may have broken down, but the van was going to get a lot of TLC.

Friday got lost in diagnosing these issues and beginning the engine mount and exhaust fix. Andrew had to remove the engine mount, but he has an ingenious system for having the engine supported by the frame of the van itself - but unfortunately, it meant we couldn’t sleep in the van. The engine was currently being supported by our bed platform. The work wasn’t all going to get done on Friday, so we headed off to a hotel for the night, where we could enjoy showers and laundry and the van stayed with Andrew.

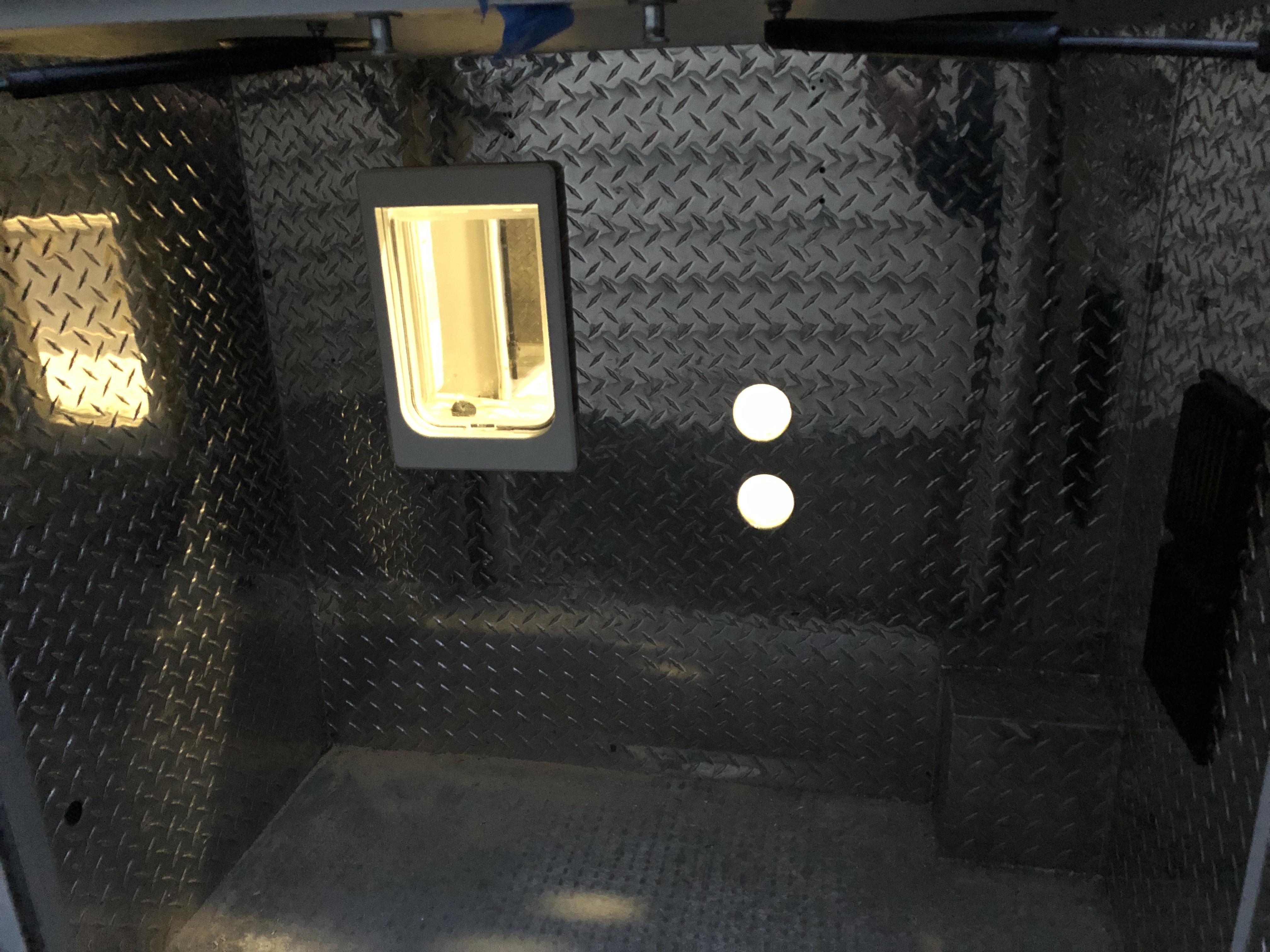

Saturday morning, we debated what we should do. Should we try to rent a car to get to Overland Expo? There were still two days left - which would be better than nothing. Or should we be responsible and go work on installing our new sunroof, which had arrived at Andrew’s before we did? In the end, we decided that although the sunroof install seemed simple enough, we should tackle it before heading off to Overland Expo. The simple things always seem to take for fecking ever. So we got a cab to take us over to Andrew’s so we could work on the sunroof install.

Five hours later, we had a beautiful new sunroof installed, and it was around 3:15 - just enough time for us to get to the car rental place before they closed at 4, and try to get out to Overland Expo to register before HQ closed at 5. Andrew wasn’t done with the van yet, and wouldn’t be until possibly sometime Sunday, so we were just hoping to enjoy OE for a few hours on Sat, come back and sleep in the van, and drive out again on Sun for the last day. We headed out with the dogs, arrived at the car rental place… and discovered that they had no more cars. They’d had cars available in the morning, but by the time we got there toward the end of the day, they’d all been rented. And none of the other rental places were open because it was late in the day on Saturday, or else it would take too long to get a cab and get to a rental place and then have time to get out to OE to register before HQ closed for the day… so we gave up, had a late lunch and wandered around Flagstaff.

We spent some time debating why the Universe had wanted us to miss Overland Expo. We’d seen signs that the dogs might have had problems there - people kept trying to pet them, Ben kept barking at people and in the back of our mind was the worry that ‘dido would bite someone. But we’d been looking forward to Overland Expo for so long! They were “our people” and we were dying to check out all the cool vehicles, the vendors who might have useful stuff for us, and the classes - particularly the class on traveling internationally with dogs.

In the end, I was convinced that we had missed Overland Expo so Andrew could work on our van over the weekend. He kept discovering stupid stuff that the people who had done the engine conversion had done, and I was convinced that the van would run better than ever, and be much more mechanically sound, after Andrew had his way with her. Then we’d still have two weeks of vacation left for wandering around - maybe we could hit Yosemite, and Redwoods, and Yellowstone before heading home. All places I’d wanted to see as long as I could remember, and Kay was down for the plan.

At some point Saturday, we attempted to reconnect the power and there was a bigger spark when the negative ground made contact. We poked around for a few minutes and discovered the bare wire that was making contact with the chassis. THAT was the real culprit that had blown our shunt and shut down our electrics. If the shunt hadn’t been there and failed under the short condition, we might have had a mess of melted wiring. Huzzah shunt! A little electrical tape temporarily fixed the problem, but it’s yet another thing I’ll need to address when we get home.

Sunday was spent hanging around with Andrew while he worked on the van. He finished up the work he was going to do on the exhaust and engine mount, and had moved onto installing our new turbo injection pump. We’d had a turbo engine, but an “eco” injection pump that didn’t fully take advantage of the turbo. We were expecting a nice uptick in power with the new pump. That, combined with the fact that our exhaust gasket wasn’t leaking all over the engine and we had now properly addressed the air filter, led us to believe we might have good performance again, and we should see our gas mileage improving.

Andrew also installed a bodge for our fuel system - a line off the tank with a fuel filter on the end, to keep rain from getting into the tank but letting us run with the filler cap on without forming a vacuum. Some prior owner had helpfully removed the expansion tanks and plugged up the hole on the fuel tank, so we had been driving along with that the whole time. Andrew’s bodge wasn’t a long-term solution - we’d still need to install some expansion tanks and do it properly when we got home - but it would get us on the road and we wouldn’t have to do our Tyvek bodge anymore.

Turbo injection pump installed, Andrew buttoned things up and went for a few test drives to tweak performance. He’d tuned it in his Rabbit, but it was performing differently than expected in our van, so he was busy adjusting the idle and the max fuel and the max rpms. This also turned into some time spent dealing with our throttle cable mount, which was yet another poor design that needed some tweaking to respond with the full range of motion it should have under throttle. Yet another stupid thing that Andrew helped to smooth out from the wonky engine conversion.

Shortly before dark, we called it and decided it was “good enough.” Andrew buttoned things up, we paid him for his time - a lot of time, but we felt it was totally worthwhile and were very appreciative of him working us in unexpectedly - and we hit the road to the local KOA. The plan was to head off to the Grand Canyon in the morning, and then onward toward adventure!

We had missed Overland Expo entirely, but we still had two weeks of vacation left and the van should be running better than ever after all the work we’d had done. It was a bittersweet weekend, but I was happy to have all of those issues addressed, and was pleased with how smooth the van felt as we drove up to the KOA. Everything was going to work out.