Can’t stop making holes

We set to work on the cat box / heater / grey water compartment. At the heart of it is a backwards “h” shaped “box” thing [I’ll get you a picture after it’s installed]. The litter box will be on top. The Propex will be below with air tubes going out through the right wall of the “h” and then into the compartment. To the right of the wall dividing the compartment (the tall side of the “h”) will be 2 six gallon water jugs that we intend to use for grey water. I wanted something that was really easy to empty and get in and out of the vehicle. Dump stations will rarely be an option.

the h box

The first step was to cut a hole for the cat flap so that she can get to the cat box. Some of the cuts required a fair amount of contortion.

contorting for the cat flap

The whole process dragged on into the evening. It’s getting dark so early these days, but we got it done.

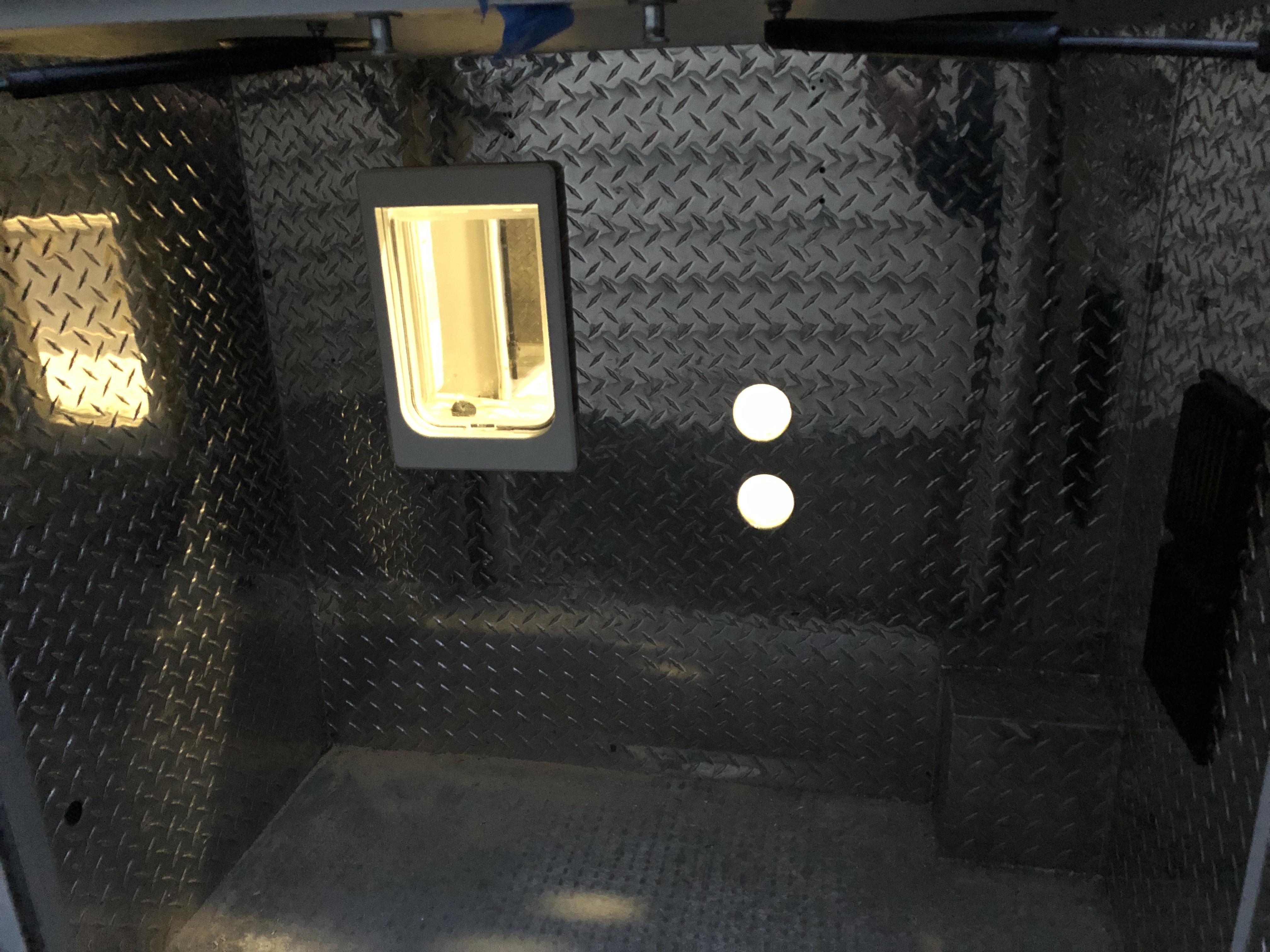

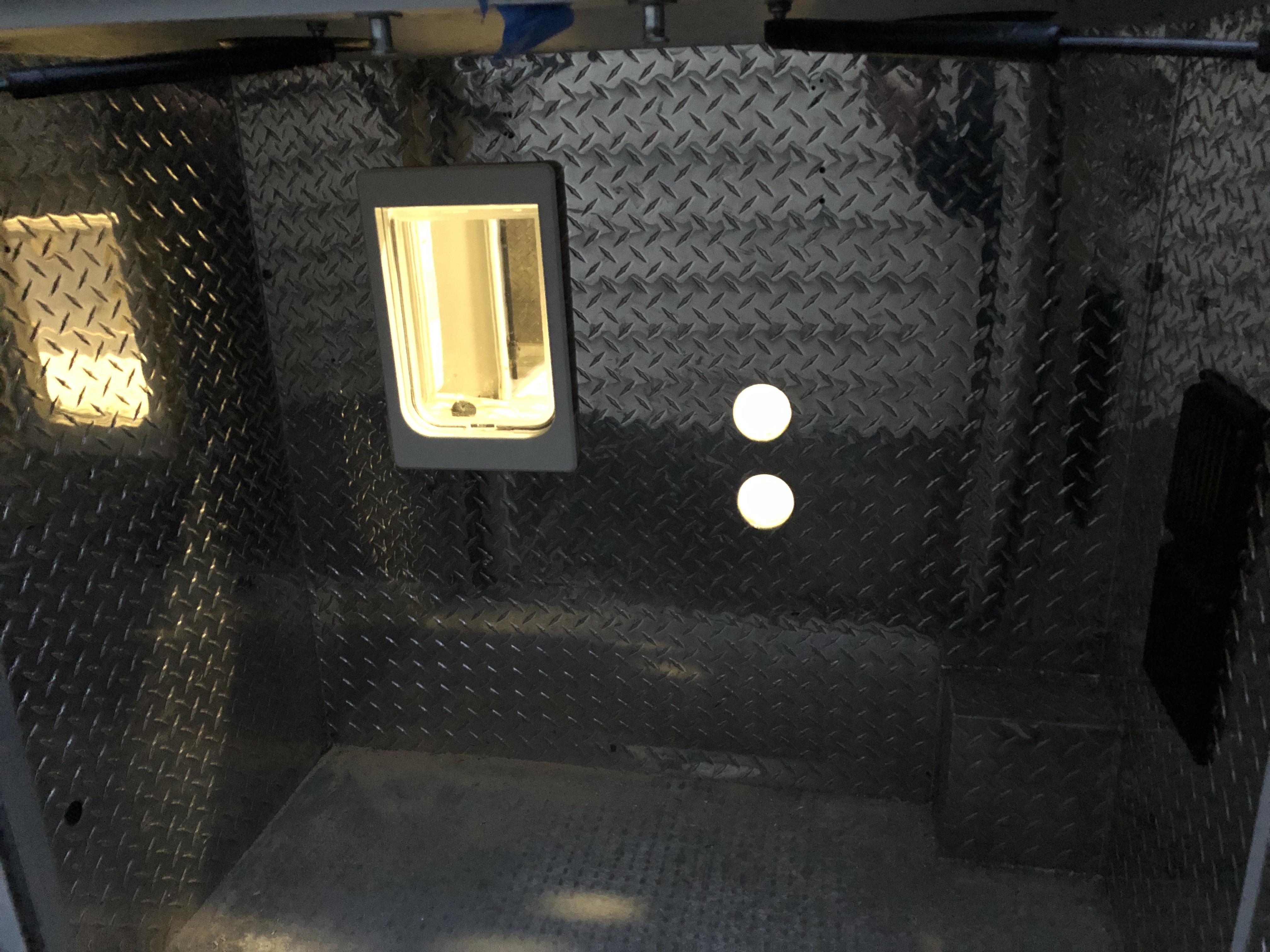

cat flap and heater holes

Before we started that cutting we made one hole from the outside in, after putting the “h” in place and setting a cat box on top of it. That hole defined the location of the bottom right corner of the cat flap. Then we went inside and made lots of careful measurements, and debated if it was straight or not. There more holes from the inside and we were ready to use the angle grinder and jig saw to finish the hole.

That first hole was a bit surprising because we definitely went all the way through, but we couldn’t see it. Turns out the drill bit just pushed the Formica away from the wall. I tested it out and it was actually pretty loosely attached. Thinking no Formica would be better for attaching the wood we’ll eventually be adding I gave I pull and it came off quite easily. Yaaay.

first Formica removal

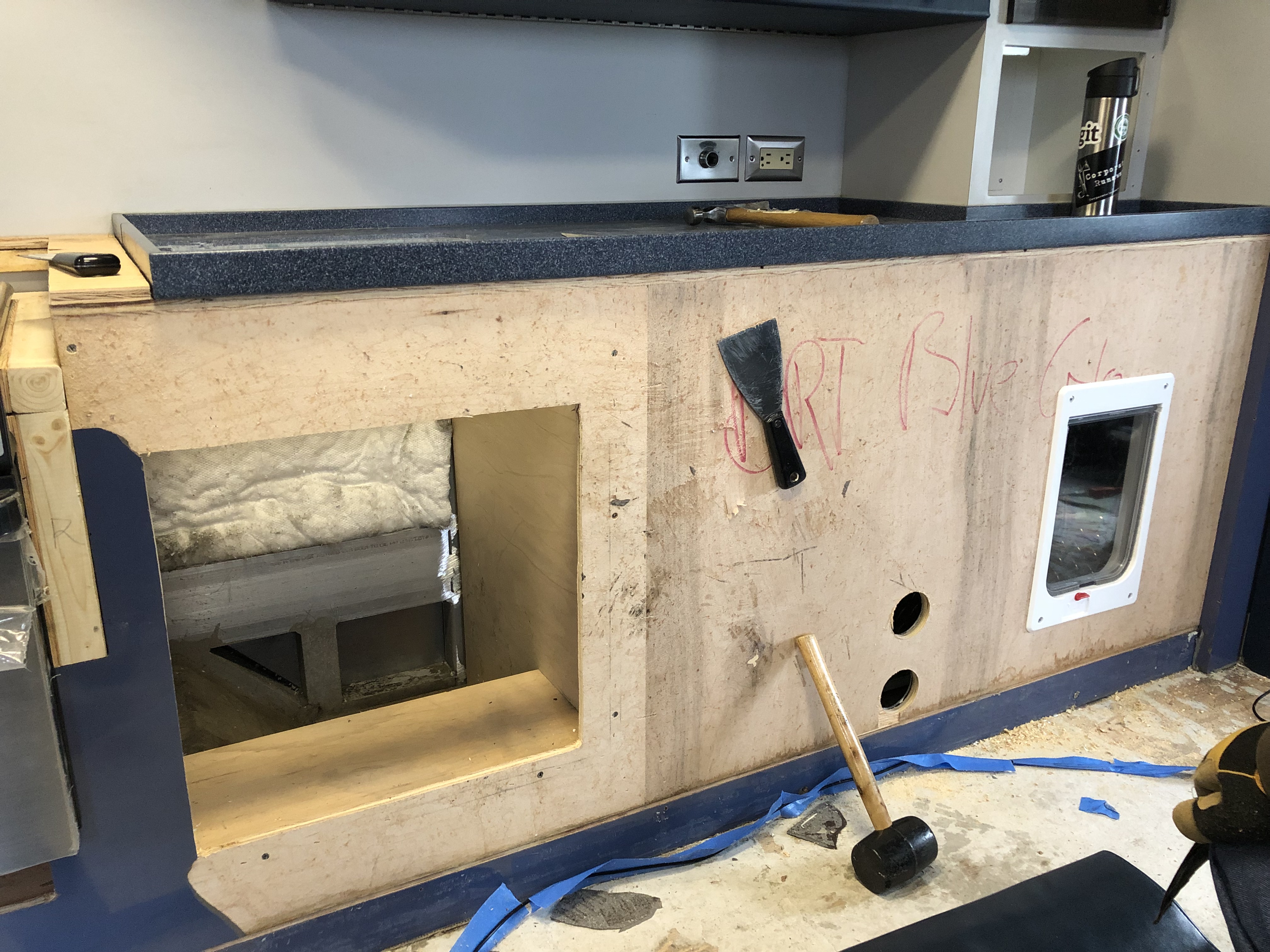

Of course, it was just that one pice that came off easily. There have been hours of pounding a paint scraper with a rubber mallet to force the well glued Formica away from the wall. Chisels were a no-go because they kept wanting to take wood with them.

We figured we’d just do this half and then sand the rest of the Formica. Unfortunately P.L. Custom chose a really good Formica which is almost impossible to scratch up even with an orbital sander. Means they’ll stay really clean. Also meant we had to remove a lot of Formica.

formica removal tools

The white Formica is more fricative so it should be amenable to the adhesive we’re going to be using. Just to be safe i went over it with 30 grit sandpaper. I made the executive decision that we would not be removing the white stuff because it would require removing and then reinstalling way too many doodads.

Dachary ended up getting a bad headache today so after helping a little with the Formica, switched to a more supervisory / moral support role.

dachary supervises

From this vantage point she noticed an interesting piano hinge under our rear control panel. Our theory is that they want it to be easy to get in and service the electronics behind the panel but we haven’t figured out what needs to be undone to make the latch swing free. I think we’ll need to break out the borescope. Even if we find something I’m not sure we’ll be able to reach it, but… we’ll see.

…

In the evenings I’ve been digging into the question of what ham radio(s) to install. We were planning on installing a Kenwood TM-D710GA, which is a pretty nice rig, and one our CERT team uses, so our usage experience would be transferable during deployments.

The problem is, I really want to do some long distance contacts from National Parks (POTA) and that means longer wavelengths that that radio can’t do. I wanted to combine that with a nice HT rig like the icom IC–7300 which looks like an absolute joy to use and gets incredible reviews but is almost another $1k (not counting antenna).

I note this now because on Black Friday we’ll be near a Ham Radio Outlet store, and they have sales, and no sales tax in NH, and I have to figure out which radio(s) to get, but ham stuff isn’t cheap, and we’re both currently unemployed. We’re currently debating how to meet the goal of having a useful ham radio setup we’ll actually enjoy using, and not going broke.

Side note: both currently unemployed because we were both totally burnt out, and desperately needed the mental break. So, we’re living off of savings until one of us gets a job, or finds some other way to bring in money. Mostly, this conversion project is a really good way to work on something different, where we can see real progress, and use different parts of our brain. That being said, it’s taking way longer than expected… and way more trips to Home Depot…holy crap!